Knot a Problem

This page is designed from helpful information that we have learned over the years. You will notice the word "Always" before each one, there is a reason for that!!!

1. Always remember that even though our wood is premium grade from the heart of the tree, these boards are all natural (not manufactured) boards so they may have some slight marks or defects. Some boards but not all may need light sanding depending on the look you want for your project. This is all natural hardwood and what distinguishes your deck from the products that are not true Brazilian Hardwood Decks. Any marks or slight imperfections give your deck character or can be easily sanded.

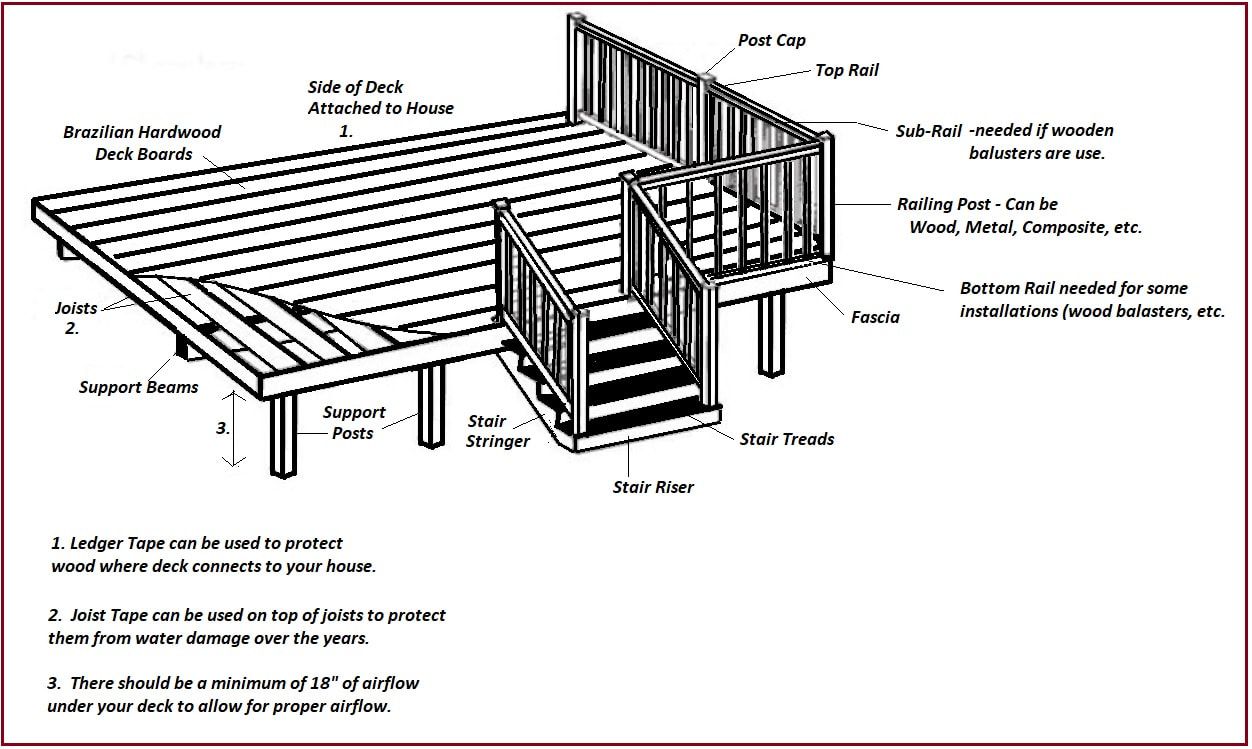

2. Always check with your local county code before starting your new deck project. The codes vary from county to county, especially for railings and handrails.

3. Always consult with your contractor (if you have one) to make sure that you are both on the same page for your wants and needs. We will be happy to look at your drawings for you to help determine what you need for your new deck.

4. Always order a few extra boards. We know that the Brazilian Hardwoods are not cheap, but shipping or milling on just a couple of boards can cost a fortune due to the fact that shippers have a minimum that they charge.

UPS will take up to 8' in length and up to 150 pounds, so this is an option with shorter boards if you do fall short.

If you do have any extra boards, you can always use them for planters, a bench or anything your imagination comes up with for your new deck!

5. Always let your wood acclimate to your climate. Make sure it is stored in a place that it cannot get wet until you install it. Make sure it is stored with stacking sticks between the boards and that it is off of the ground. If it is outside, make sure that it is covered, but make sure to leave ventilation so air can still circulate around your wood. If you store your wood in a garage, make sure to have ventilation for air circulation and that the area does not have heat or air conditioning. If the wood came from a warehouse close to you, let it acclimate for a few days and if it did not, you should wait a minimum of 7-10 days before installing it.

6. Always pre-drill your hardwood before installing your fasteners. It may not be noticeable now but your boards may crack or check down the road in the areas that are not pre-drilled.

7. Always replace the Wax on the ends of any board that you cross cut. It really does help to prevent checking or cracking on the ends of your boards down the road. Ipe Seal End Wax is inexpensive, easy to do and will be well worth it in the long run.

8. Always use Stainless Steel Screws or Fasteners. The Stainless Steel will not rust plus it will not react with your pressure treated joists. 305 SS is the norm but if you are near Salt Water or using Garapa, always use the 316 SS.

9. Always remove any metal shavings from your deck that may be left from fasteners or metal railings that were installed. Most woods will react with the metal shavings and these shavings will leave black marks or spots on your new deck. in most cases cleaners will not remove these marks and you will NOT need to sand your wood before applying your finisher.

10. Always try your finisher on a scrap piece of your deck boards to make sure that you like it. Please read the Finish(er) Line info under accessories/finishers. There is a lot of helpful information on this page.

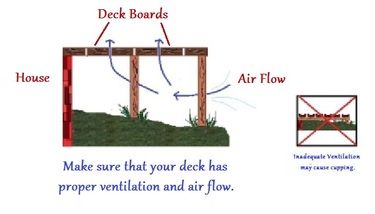

11. Always make sure to have proper deck ventilation under your deck. Air needs to be able flow under and around your deck boards and posts. If you are skirting your deck make sure to have areas where air can flow through (such as vents). If air can not flow through and dry your boards on the bottom from moisture that accumulates under your deck, your boards will cup because the top of your boards will dry and the bottom will not.

We ship from one of our many warehouses around the country directly to your home or job site anywhere in the continental U.S.

We also deliver to shipyards in the U.S. for overseas projects.