Cutek© America

Cutek® Extreme

Cutek is a high-grade synthetic oil developed in Australia which is one of the harshest climates in the world.

The CUTEK approach to protecting wood is completely different to most other wood care systems as it penetrates and continues to migrate into the wood to protect from within.

Unlike most other wood coatings, CUTEK will not form a film so it doesn’t need sanding or chemical stripping for continued care. Once CUTEK has been fully absorbed into the wood, it stays inside long term to help reduce moisture getting in and out. This greatly reduces the potential for splitting, warping, checking, cupping or other wood-related movement problems.

CUTEK provides a much higher level of protection over other coatings when it comes to keeping your wood straight and stable for long-term use.

Info for Coverage:

New Hardwoods - 400 - 800 s.f. depending on species.

Old Restored Wood - 300 - 400 s.f. depending on species.

New Wood - rough or band sawn - 180 - 300 s.f. depending on species.

Shingles and Shake - 84 - 212 s.f. depending on species.

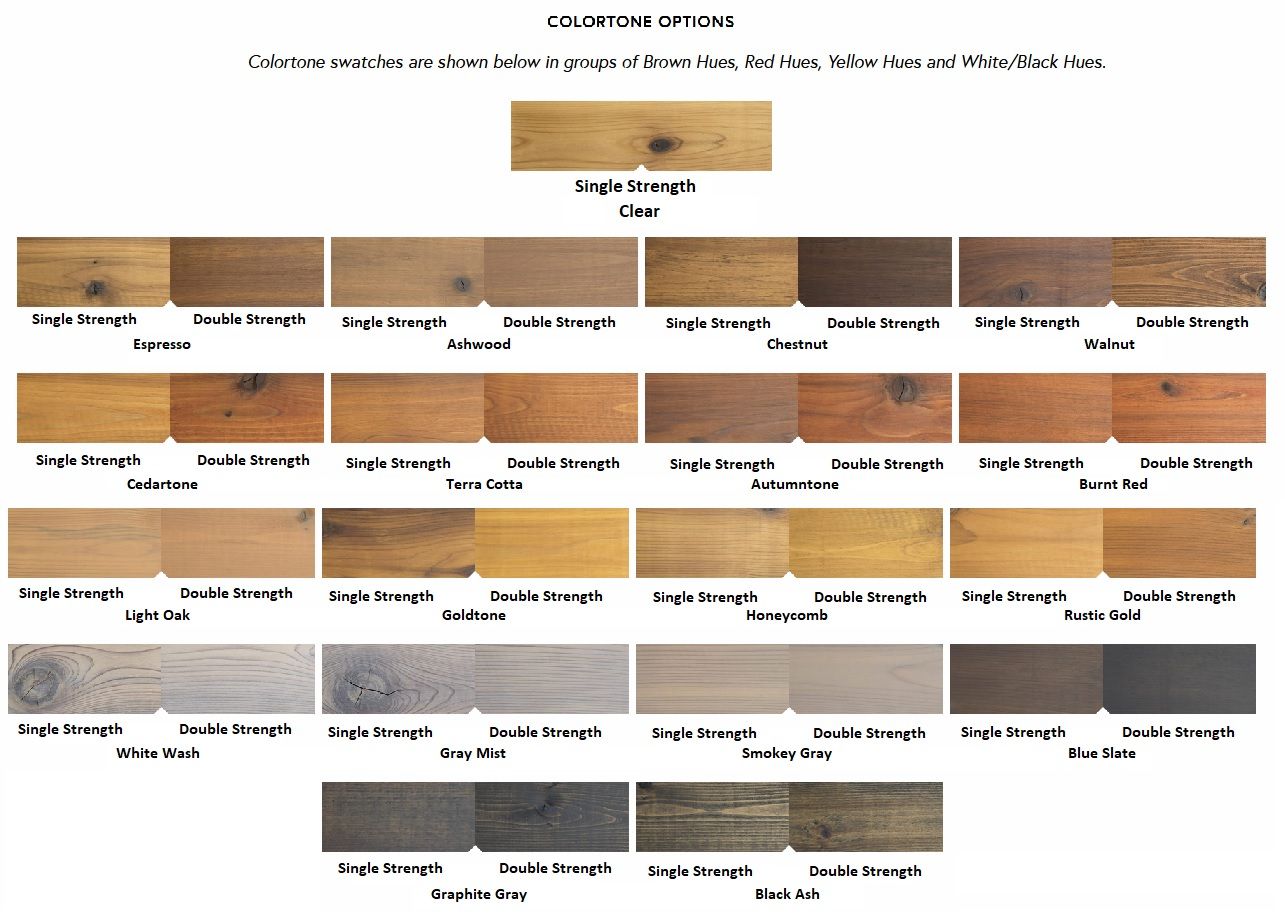

Colors

All pictures shown are of actual wood samples of the selected species. Each sample was coated with 2 coats of CUTEK® Extreme (including the added Colortone) at single or double strength. The wood sample picture labelled “CLEAR” has been included to show the original color of the wood for your ease of reference (a Colortone must be add for UV Protection). Please note: the color, species, age and condition of your wood to be coated will impact the final color and finish of all CUTEK® products. The Colortones on the CUTEK® website are representative only and may look different when applied to your specific wood project. Always try Cutek® on a small area or sample piece BEFORE coating your entire project.

Cutek Extreme Oil $130.00 each

Cutek Wood Cleaner $59.00 each

Cutek Colortone Pigment (any color) $13.95 each

To Make Tigertone which is perfect for Tigerwood Decking - add 1/2 Can Burnt Red Colortone and 1/2 Can Walnut Colortone to your Cutek Oil.

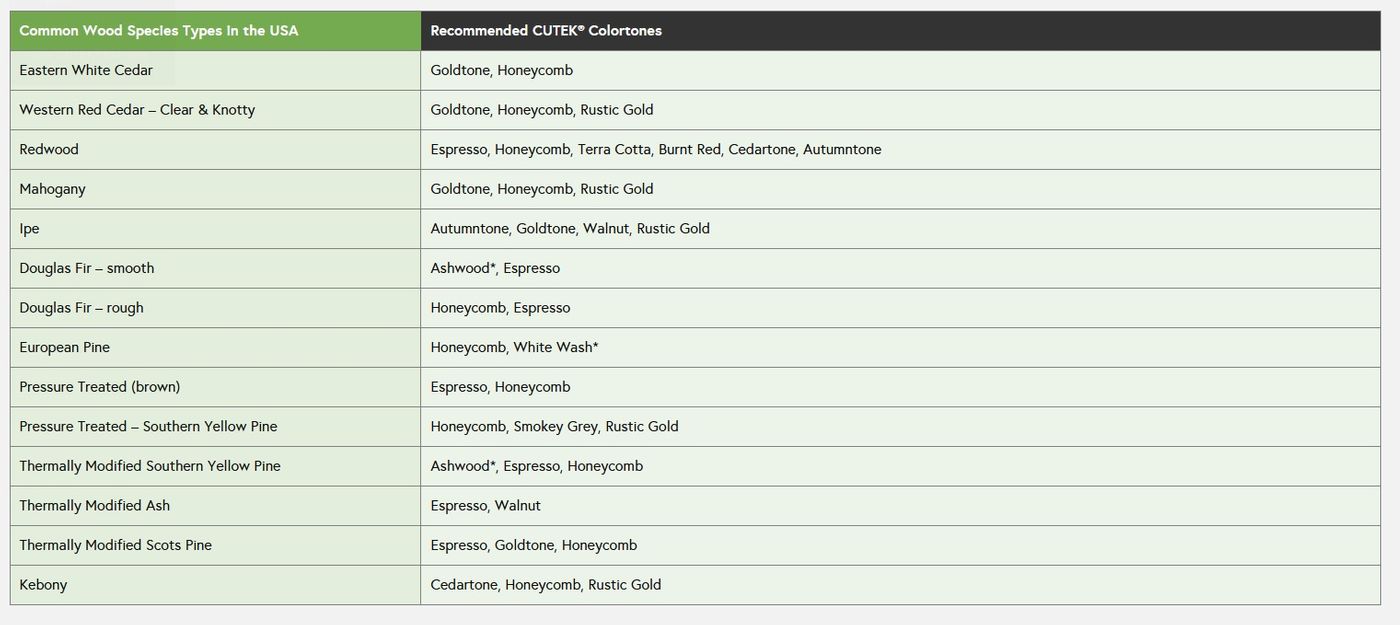

Selecting the right CUTEK® Colortone

Our CUTEK® Colortone system is designed to enhance your wood color and grain pattern. With this in mind, you need to think about your original wood choice and the color it most represents. Is it Dark, Light to Golden, Brown, Red or a combination? Here are a few common examples to help you understand:

Western Red Cedar is a reddish brown, so Rustic Gold is a nice choice.

Redwood and Mahogany is a ight reddish brown to darker reddish brown, so Terra Cotta or Autumntone will look similar on new smooth/sanded wood.

Douglas Fir is a light brown with a hint of red and/or yellow, so Espresso is a nice choice.

Eastern White Cedar is a light whitish to straw yellow, so Goldtone or Honeycomb will look similar on new smooth/sanded wood

Changing the original color of any wood:

For horizontal walk-on surfaces such as decking, walkways, docks, etc. we recommend you select a CUTEK® Colortone that is the closest match to the wood you have selected, rather than attempt to change the color. You can talk to any of our retailers for advice.

For cladding and screening, a much higher intensity of color can be achieved which can completely change the original tone of the wood. Even a very light colored wood species can become an almost solid Black, Gray, Red, Brown or Gold if the wood surface is suitably rough and more coats or a higher pigment (Colortone) has been added.

In some circumstances you can double your CUTEK® Colortone to achieve bolder effects on rough or brushed wood. We advise that you contact us to discuss this option in more detail as we want to ensure you have the best information possible.

Please keep in mind that trying an instant weather look on dark woods such as Ipe may not work, please try it on a sample piece first.

WOOD PREPARATION

New wood

New wood should be clean, dry and free from any existing paints, stains or sealers.

For best results, clean your wood using ProClean per our guidelines. This will help remove stains, millglaze and brighten your wood. It will also open and raise the timber grain that once dry, will allow for better penetration of CUTEK oil. Color durability (if using a Colortone), will be enhanced when following this cleaning process.

Where possible, sanding the timber/deck using 80 grit will provide an ideal surface in preparation for application of CUTEK oil. Ensure all dust is removed by blowing, sweeping or vacuuming the sanded timber.

Existing wood with an existing coating

Wood must be clean, dry and free from any existing paints, stains or sealers. Cleaning alone isn’t enough to remove existing paints, stains or sealers so a combination of sanding and stripping is required to remove all film.

IMPORTANT – CUTEK oil relies on full penetration into the wood and failure to remove any existing paints, stains or sealers will not allow CUTEK Oil to penetrate, dry and cure as it should.

After sanding and stripping all existing paints, stains or sealers, follow up using ProClean should be carried out to neutralize, clean and brighten your wood in preparation for CUTEK Oil.

COLOR

If you want to keep the natural color of your wood longer, using a Colortone mixed into the CUTEK Extreme Clear Oil is a must.

We always recommend testing CUTEK with color on a scrap piece of your wood before applying. We have a wide range of pre-mixed sample cans so you can test your wood with an application of two coats, allow to fully dry over a few days in full weather exposure (keep in mind if your piece of sample wood gets wet, it will cup because it is not fastened down). This is the best way to evaluate our CUTEK with color, then you can move forward knowing what your project will look like once you are finished with your project.

Wood projects where just CUTEK Extreme clear oil is used will lighten and eventually silver over time while still remaining protected. This represents a low maintenance option. If later on you desire to bring back the natural color of the timber, you can clean using ProClean and pressure washing followed by an application of CUTEK oil (clear or with one of our available Colortones).

APPLICATION AND WATER

Painting 101 is that you shouldn’t paint wet wood and you shouldn’t paint in the rain or in damp conditions. The same applies when using our CUTEK oil.

Wood needs to be clean and dry - if rain is due in the next 12 hours, delay your application of CUTEK oil until there is more favorable weather in the forecast.

If you already applied the first coat and it rains within a few hours, remove any water excess from the boards, wait until they dry and then apply a second coat.

DRYING TIME

Drying time can vary significantly depending on the weather, temperature and humidity, timber species density and moisture content plus the amount of CUTEK oil applied in any one application.

You should allow at least 24 hours drying time before the application of your second coat of CUTEK oil and if in doubt, just wait another day before going ahead with the second application.

Wood should feel dry to the touch and non greasy before the application of your second coat of CUTEK Oil.

PRE-COATING YOUR WOOD

The first coat should be in all six faces (if possible), for best results.

Second coat can be only in exterior face.

HOW MUCH SHOULD I APPLY?

In hardwoods you should apply thin coats.

Softwood and Thermally Modified timbers will naturally take up more CUTEK oils with the first application. It’s best to apply a thin coat for your second application.

Always apply generously on end grain.

NO EXPERIENCE NEEDED

CUTEK is fast and easy to apply and the great news - you don’t need to be a Pro to get a Pro finish!

CUTEK diffuses into the wood and doesn’t leave lap marks.

CUTEK oil can be applied in direct sun even on the hottest days and you won’t get drips, runs, sags or overlap marks.

DRY WOOD

All wood needs to be dry with a moisture content of 17% or less.

A good way to tell if you wood is dry enough for your finisher is to sprinkle some water on your deck with your hand and if it soaks in within 30 seconds, your wood should be ready to apply your sealer.

Application and Maintenance:

Stir the contents of the CUTEK® Colortone thoroughly and add to the clear CUTEK® Extreme oil as follows:

• For 0.95 gal of CUTEK® Extreme – add 1 x 3 oz Colortone

• For 5 gal of CUTEK® Extreme – add 5 x 3 oz Colortones

Thoroughly stir combined mixture from the bottom of the can BEFORE AND DURING use.

Failure to do this may result in inconsistent color.

For best results, one coat of clear CUTEK® Extreme should be applied to all faces of the wood prior to installing, with a second and third coat of Colortoned CUTEK® Extreme applied to the top surface, after installation, once the prior coat is completely dry and non-greasy.

If applying post-construction, apply two thin coats to all accessible wood surfaces, ensuring the first coat has completely penetrated/diffused (dried) before applying the second coat.

Colortoned CUTEK® Extreme will lighten/fade faster in full weather exposed areas whereas wood in protected areas will retain color with minimal maintenance over time.

CUTEK® Extreme is designed to gradually fade, ware, or erode over time and with use rather than peel, split or crack. Rejuvenation of wood coated with CUTEK® Extreme is a simple, fast and cost-effective process.

Clear or Colortoned CUTEK® Extreme should be reapplied as frequently as necessary to retain the natural beauty and color of your wood. Assessment of this is subjective and it is important to realize that color durability varies widely according to many factors including the age and porosity of the wood, species, situation, exposure to the weather and how rough the wood surface is.

Typically, horizontal exterior wood surfaces exposed to full weather such as decks and handrails will require recoating more frequently (initially after 6-12 months), while other surfaces such as vertical rough-sawn cladding will need recoating less often.

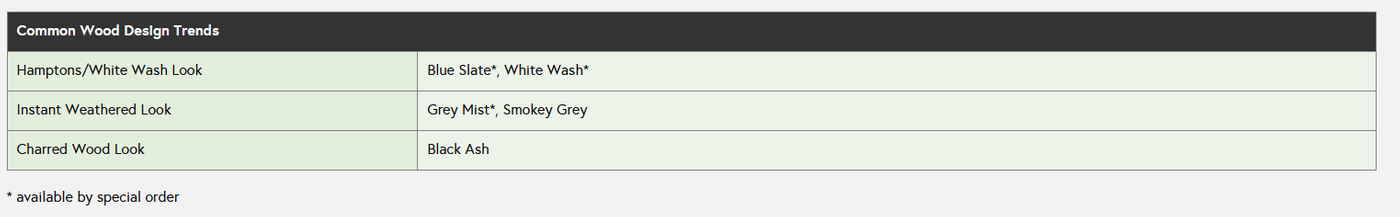

Tigerwood Deck with Cutek©

This deck has Cutek Oil applied to it and gorgeous. It is over 20 years old!